Impazamo yefomathi ye-imeyile

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Thermocouple vs Temperature Sensor: Understanding the Difference

When it comes to measuring temperature, choosing the right tool for the job is crucial. Among the various options available, thermocouples and temperature sensors are two of the most commonly used devices. While they both serve the essential function of measuring temperature, they do so in different ways and are suitable for different applications. In this blog, we will delve into the differences between thermocouples and temperature sensors, exploring their respective advantages and disadvantages, and helping you understand which one might be the best fit for your needs.

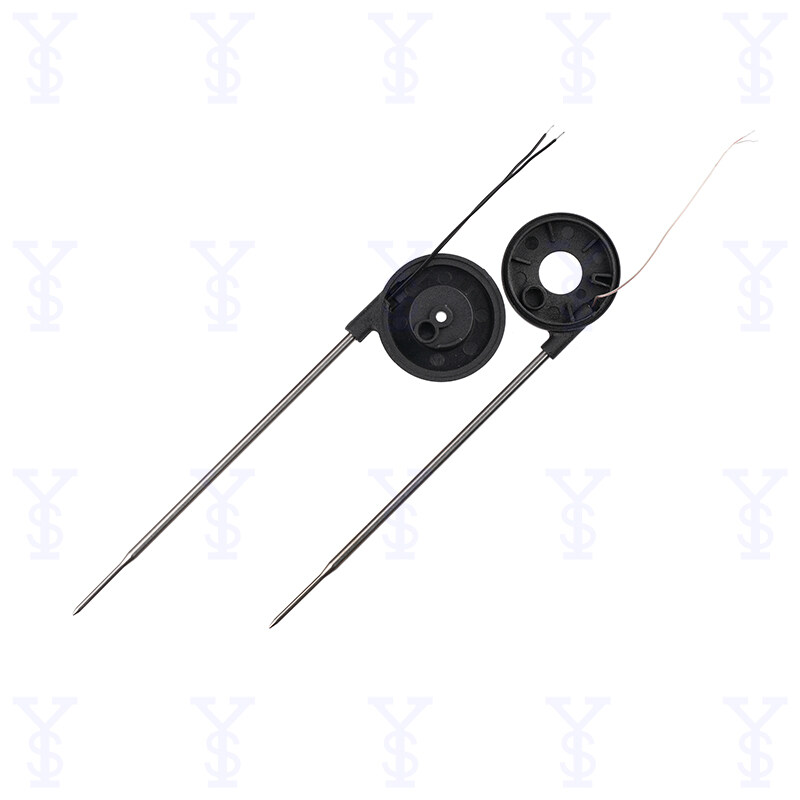

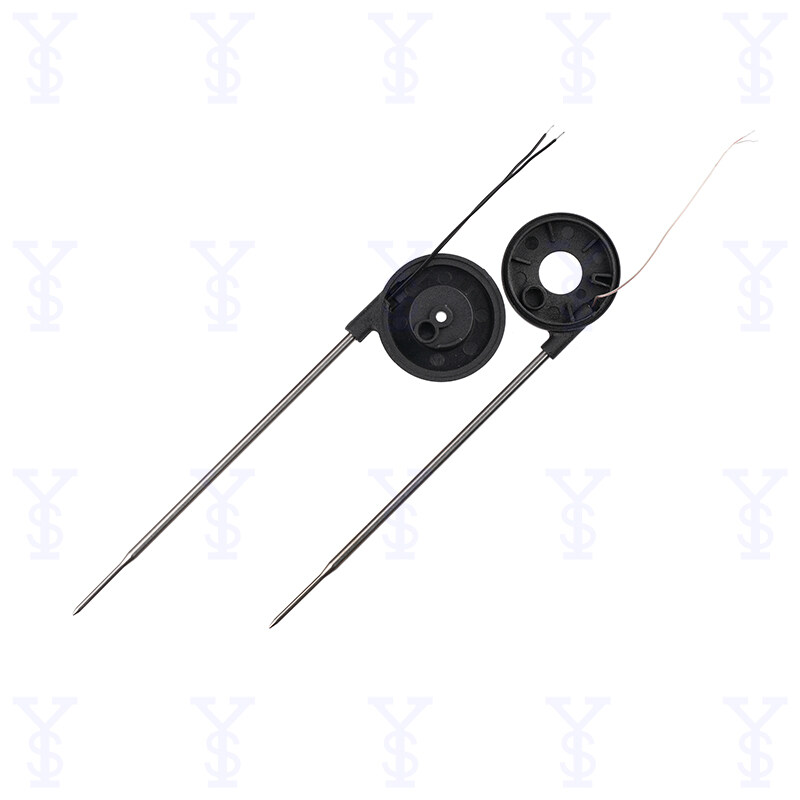

What is a Thermocouple?

A thermocouple is a type of temperature sensor that consists of two different metals joined together at one end. This junction creates a small voltage when exposed to heat. The voltage generated is proportional to the temperature difference between the junction and the other ends of the metals. This voltage can be measured and translated into a temperature reading.

Types of Thermocouples

There are several types of thermocouples, each suited for different temperature ranges and environments. Some common types include:

- Type K: Made from Chromel and Alumel, this is one of the most common thermocouples, offering a wide temperature range from -200°C to 1260°C.

- Type J: Comprising Iron and Constantan, it’s ideal for temperatures ranging from -40°C to 750°C.

- Type T: Consists of Copper and Constantan, known for its accuracy in the range of -200°C to 350°C.

- Type E: Made from Chromel and Constantan, it offers high sensitivity and a temperature range of -200°C to 900°C.

Each type of thermocouple has its specific uses, and choosing the right one depends on the temperature range and accuracy needed for your application.

What is a Temperature Sensor?

Temperature sensors, on the other hand, are a broader category of devices designed to measure temperature. They come in various forms, including:

- Thermistors: These are resistive temperature devices that change resistance with temperature. They are highly accurate over a limited temperature range and are often used in digital thermometers and electronic temperature measurements.

- RTDs (Resistance Temperature Detectors): RTDs measure temperature by correlating the resistance of the RTD element with temperature. They are known for their high accuracy and stability over a wide range of temperatures.

- Semiconductor Temperature Sensors: These sensors use the temperature-dependent voltage characteristics of semiconductors to measure temperature. They are commonly used in consumer electronics and HVAC systems.

Each type of temperature sensor has its advantages, and the choice depends on factors such as the temperature range, accuracy, response time, and the specific requirements of your application.

Comparing Thermocouples and Temperature Sensors

Accuracy and Precision

One of the primary differences between thermocouples and other temperature sensors is accuracy. Generally, thermocouples have lower accuracy compared to RTDs and thermistors. Thermocouples can be affected by factors such as oxidation and drift over time, which can impact their precision. In contrast, RTDs and thermistors are known for their high accuracy and consistency.

For applications where precise temperature measurement is crucial, such as in scientific experiments or high-precision manufacturing, RTDs and thermistors might be the better choice. However, for applications that can tolerate slight variations in temperature or where cost is a significant factor, thermocouples can still be quite effective.

Temperature Range

Thermocouples are renowned for their ability to measure a wide range of temperatures. They can handle extremely high temperatures, making them suitable for applications in industrial settings, such as furnaces and kilns. For instance, a Type K thermocouple can measure temperatures up to 1260°C, which is beyond the range of most RTDs and thermistors.

Temperature sensors like RTDs and thermistors typically have more limited temperature ranges. RTDs are suitable for temperatures from -200°C to 850°C, while thermistors generally operate within a narrower range. Therefore, if your application involves extremely high or low temperatures, thermocouples might be the preferred choice.

Response Time

In terms of response time, thermocouples usually have a faster response compared to RTDs and thermistors. This is because the thermocouple junction is small and has a low thermal mass, allowing it to quickly respond to changes in temperature. This feature makes thermocouples ideal for applications where rapid temperature fluctuations are expected.

On the other hand, RTDs and thermistors have a slower response time due to their larger size and thermal mass. However, this difference in response time may not be significant for many applications, especially if the temperature changes are gradual.

Durability and Stability

Thermocouples are generally more robust and durable compared to RTDs and thermistors. They can withstand harsh environments, including extreme temperatures and corrosive substances, making them suitable for industrial applications. For example, Type K thermocouples are commonly used in environments where the temperature can reach several hundred degrees Celsius.

RTDs and thermistors, while highly accurate, can be more susceptible to damage from extreme conditions. They may require more careful handling and protection, especially in environments where high temperatures, vibrations, or corrosive elements are present.

Cost

Cost is another significant factor to consider. Thermocouples are often more cost-effective than RTDs and thermistors. They are relatively simple in design and manufacturing, which makes them more affordable. For applications where budget constraints are a concern, thermocouples can provide a reliable solution without breaking the bank.

RTDs and thermistors, due to their higher accuracy and more complex construction, tend to be more expensive. If your application demands high precision and you have a higher budget, investing in these sensors might be worthwhile.

Applications and Use Cases

Understanding the differences between thermocouples and temperature sensors can help you choose the right device for your specific needs. Here are some common applications for each:

Thermocouples:

-

- Industrial Processes: Thermocouples are frequently used in industries such as metal processing, glass manufacturing, and petrochemicals, where high-temperature measurements are required.

- Furnace Monitoring: Due to their ability to handle high temperatures, thermocouples are ideal for monitoring furnace temperatures.

- Automotive Testing: They are used in automotive testing to measure exhaust gas temperatures and engine performance.

RTDs:

-

- Laboratory Research: RTDs are often used in research environments where high accuracy is crucial.

- HVAC Systems: They are used in heating, ventilation, and air conditioning systems to monitor and control temperatures.

- Food Processing: RTDs are employed in food processing industries to ensure accurate temperature control.

Thermistors:

-

- Consumer Electronics: Thermistors are commonly used in household appliances and electronic devices.

- Medical Devices: They are used in medical equipment to monitor body temperature and other critical parameters.

- Environmental Monitoring: Thermistors are used in environmental sensors for monitoring weather conditions.

Conclusion

In summary, both thermocouples and temperature sensors have their unique strengths and applications. Thermocouples are excellent for measuring high temperatures and in rugged environments, offering cost-effectiveness and durability. On the other hand, temperature sensors like RTDs and thermistors provide higher accuracy and are better suited for applications requiring precise temperature control.

Understanding the specific requirements of your application—whether it’s the temperature range, response time, accuracy, durability, or cost—will help you make an informed decision. Whether you choose a thermocouple or a different type of temperature sensor, both play crucial roles in ensuring accurate temperature measurement across a variety of industries and applications.